BLAST MITIGATING (PL1)

PL1 (without bottom restraints) has been tested and shown to be capable of achieving limited damage in response to a blast load with peak pressure 75 kPa and peak impulse 1050 kPa-ms;

Protect your facility with our certified blast-resistant shutters, designed to withstand extreme pressure and prevent debris and fragments from industrial explosions.

Get a QuoteConventional roller shutters can become hazardous debris in a blast situation. This often occurs in oil and gas facilities, which experience accidental release of flammable materials resulting in a vapor cloud explosion.

To mitigate this hazard, Gliderol had developed blast-resistant shutters in consultation with ABS Consulting of the USA.

The two-phase development program includes the use of finite element analysis (FEA) to design the door system and then validate the model with a full-scale shock-tube test of the working model.

Our design approach is to allow the shutter curtain to plastically deform under blast pressure and progressively arrest the moving components of the curtain. These components are made up of elements that are connected to prevent them from becoming debris.

We achieved this with a curtain supported by horizontal steel connector rods that are attached to vertical wire ropes at both sides. The wire ropes are restrained at the top and either unrestrained (for PL1) or tethered (for PL2) at the bottom.

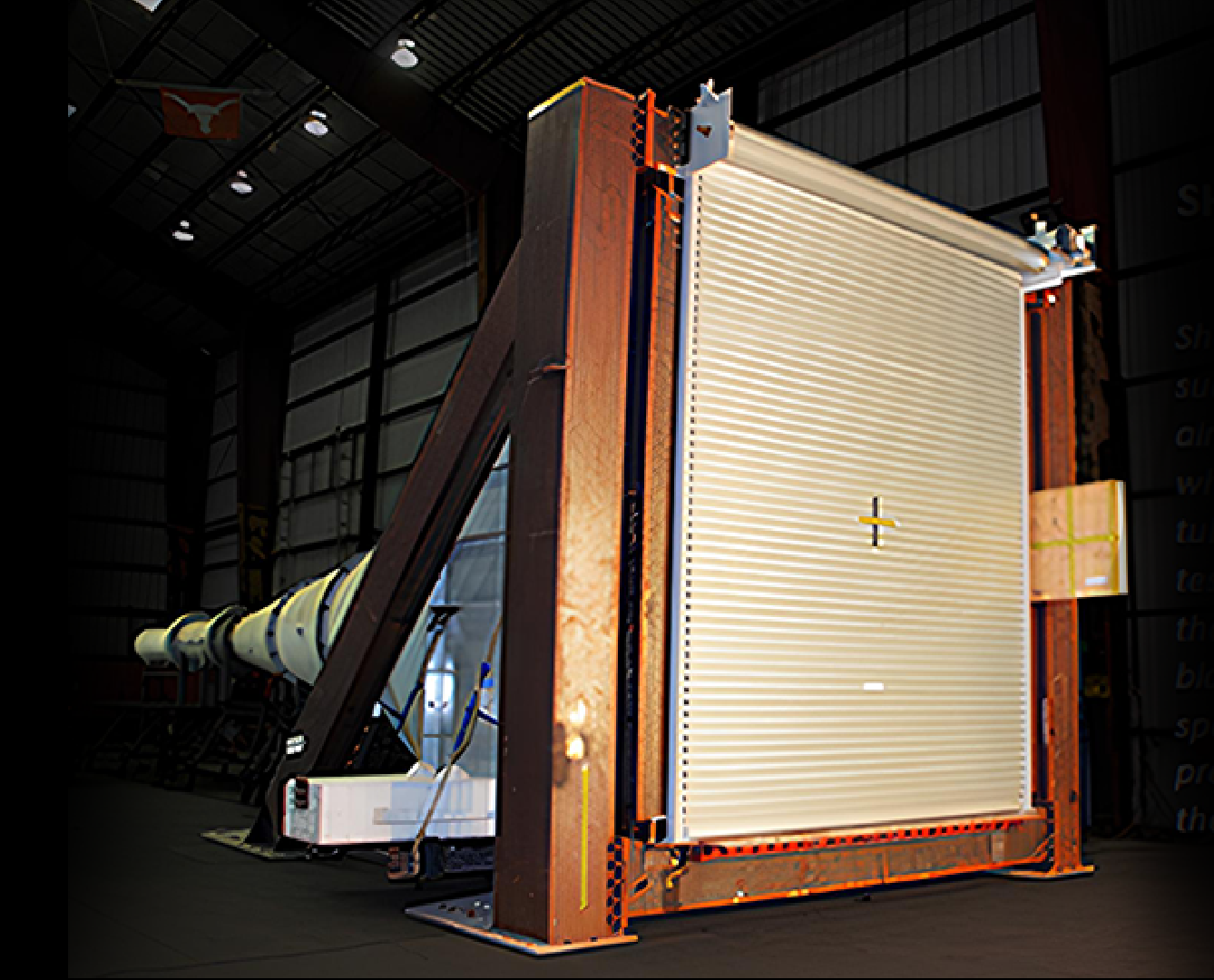

The development program of our blast shutters culminated with the shock tube testing of 2 units of full-scale working models, each measuring W 3700mm x H 4950mm.

The test results were in excellent agreement with the FEA analysis using the measured test loads for both PL1 and PL2 configurations.

In all the tests, minimal permanent damage was observed, and no debris was produced.

This validation indicates that our FEA model can be reliably used to assess the likely performance of our blast shutter for alternative dimensions or blast loads.

Blast shutters protect oil and gas facilities from explosions and fires caused by volatile fuels like crude oil and natural gas.

Factory and warehouses carry high fire and explosion risks due to concentrated flammable materials and chemicals, making blast-resistant shutters essential for safety.

Petrochemical facilities process flammable chemicals, making blast shutters critical in protecting workers.

Due to the presence of combustible materials like paper, cardboard, and batteries, blast shutters are essential in waste management facilities.

Blast shutters help protect government facilities by providing a robust barrier that enhances security and reduces risks to people, assets, and essential operations during threat events.

High-speed camera images of PL1 test

PL1 (without bottom restraints) has been tested and shown to be capable of achieving limited damage in response to a blast load with peak pressure 75 kPa and peak impulse 1050 kPa-ms;

High-speed camera images of PL2 test

PL2 is fitted with a pair of automated bottom restraint device that will work with the motor operator to ensure that the restraints will always engage whenever the shutter is in the closed position. PL2 has been tested and shown to be capable of achieving limited damage and be fully retained in response to a blast load with a peak pressure 40 kPa and peak impulse 500 kPa-ms.

PL1 will absorb blast load through large displacement, minimize blast load reactions on the structure and prevent component failure and debris generation. It will also permit egress following the blast loading.

PL2 will absorb blast load through limited displacement, minimize door response and intrusion into occupied space, and prevent component failure and debris generation.

Shock-tube testing uses a sudden burst of compressed air to create a blast pulse, which travels down the tube and is applied to the test specimen installed at the end of the tube. The blast load creates a specified positive blast pressure and impulse on the test specimen.

PL1 (Blast Mitigating)

PL2 (Blast Resistant)

As a trusted blast shutter supplier in Singapore, our experts provide tailored solutions to meet your safety and performance needs.

Contact Us